Guanhui Crane Application in 3-Layer Paperboard Lines

Given the user’s specification of cranes at three different heights, it seems likely that the production line is arranged in a vertical, multi-layer structure to optimize space, with each layer handling specific stages of production. The first layer might handle initial heavy lifting, the second layer intermediate processes, and the third layer final assembly or lighter tasks.

Guanhui Crane, located in Foshan City, Nanhai District, Guangdong Province, China, is a prominent manufacturer under the Guanhui group, known for designing and producing a wide range of standardized and custom-engineered overhead cranes, gantry cranes, and jib cranes for multiple industries across more than 60 countries on five continents, with a state-of-the-art manufacturing facility spanning over 100,000 square meters (Cranes Lifting Solution Provider | Guanhui). They are ISO 9001:2015 certified, emphasizing rigorous quality control and automated welding for efficient production.

The Role of Cranes in Paperboard Production

Cranes are integral to paperboard production lines for handling heavy and bulky materials. Research suggests their primary roles include:

Handling heavy paper rolls: Cranes lift and position paper rolls into raw paper frames, with capacities ranging from 2 to 20 tons per roll, as noted in overhead crane systems for paper mills

Maintenance and repair: During downtime, cranes move machinery parts, such as rollers or felt covers, ensuring smooth maintenance processes, as highlighted in paper mill crane applications

Material transfer: Cranes may transfer intermediate products or waste, enhancing workflow efficiency, particularly in automated setups.

Bridge and gantry cranes, like those offered by Guanhui, are ideal due to their ability to operate in confined spaces and handle multi-directional loads, improving safety and reducing manual labor, as discussed in overhead crane operations(Operations, Industries and Uses of Overhead Cranes).

Guanhui Crane’s Specific Solutions

Guanhui’s crane portfolio includes overhead and gantry cranes with load capacities from 3 to 200 tons, designed for manufacturing environments (Products – Cranes Lifting Solution Provider | Guanhui). Key features include:

- Customization:Tailored to specific load capacities and operational needs, ensuring fit for paperboard lines.

- Durability:Built to withstand harsh industrial conditions, with automated welding for box girders.

- Precision:Ensures accurate placement, critical for handling delicate paper rolls.

- Safety:Equipped with advanced features, protecting operators and maintaining production quality.

Their focus on automated crane systems, as seen in their offerings (Enhance Efficiency with Our Automated Crane System), is particularly relevant, offering semi-automated or fully-automated solutions that reduce operator fatigue and enhance efficiency in demanding environments like paper mills.

Layer-Specific Crane Applications

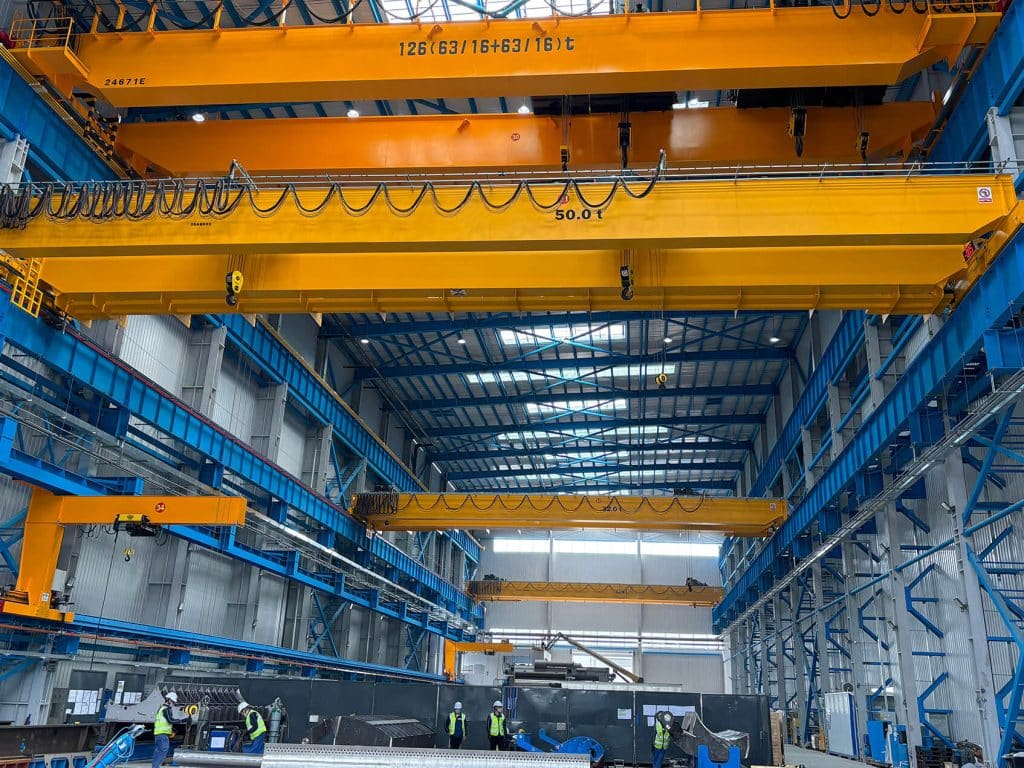

The user provided detailed crane configurations for each layer, which are as follows:

- First Layer:One 126t crane for transporting materials.

- Second Layer:Two 32t cranes and one 50t crane for transporting heavy components.

- Third Layer:Two wall-mounted jib cranes for transporting light components at workstations.

Given the capacities, here’s how they likely fit into the production line:

- First Layer (126t Crane):Research suggests this heavy-duty crane is used for the most demanding lifting tasks, such as installing or moving large parts of the production line. Given that paper rolls typically weigh up to 4.5 tons , the 126t capacity is unexpected and likely used for heavy machinery installation or moving exceptionally large components, enhancing the initial setup and maintenance phases.

- Second Layer (Two 32t and One 50t Cranes):It seems likely these cranes handle mid-range lifting tasks, such as moving smaller paper rolls or mechanical parts during intermediate processes. The two 32t cranes might be used for simultaneous operations, while the 50t crane addresses heavier components, ensuring flexibility and efficiency.

- Third Layer (Wall-Mounted Jib Cranes):The evidence leans toward these being used for light, frequent lifting at workstations, such as handling small tools or light materials, providing maneuverability and ease of use for final assembly or packaging tasks.

An example from the paper industry shows double girder bridge cranes handling paper rolls, reducing crane wheel pressure and saving investment by 35%, aligning with Guanhui’s focus on cost-effective solutions

Technical Specifications and Comparison

To illustrate, here’s a table comparing Guanhui’s crane specifications relevant to paperboard production:

Specification | Details | Applicable Layers |

Maximum Load Capacity | 3 to 200 tons | First (126t), Second (32t, 50t) |

Span Range | Customizable, up to 20.4m | All layers |

Customization Options | Bridge, gantry, jib cranes | Third (jib) |

Safety Features | Automatic monitoring, anti-corrosion design | All layers |

Automation Level | Semi-automated to fully automated | All layers |

Guanhui Crane’s bridge and gantry cranes are well-suited for three-layer multi-functional paperboard production lines, enhancing efficiency by handling heavy loads, ensuring safety, and offering customization. Their ISO certification, global experience, and focus on automation make them a top choice. For businesses in paperboard manufacturing, considering Guanhui could streamline operations and reduce downtime, with potential for further exploration into automated systems for future scalability.