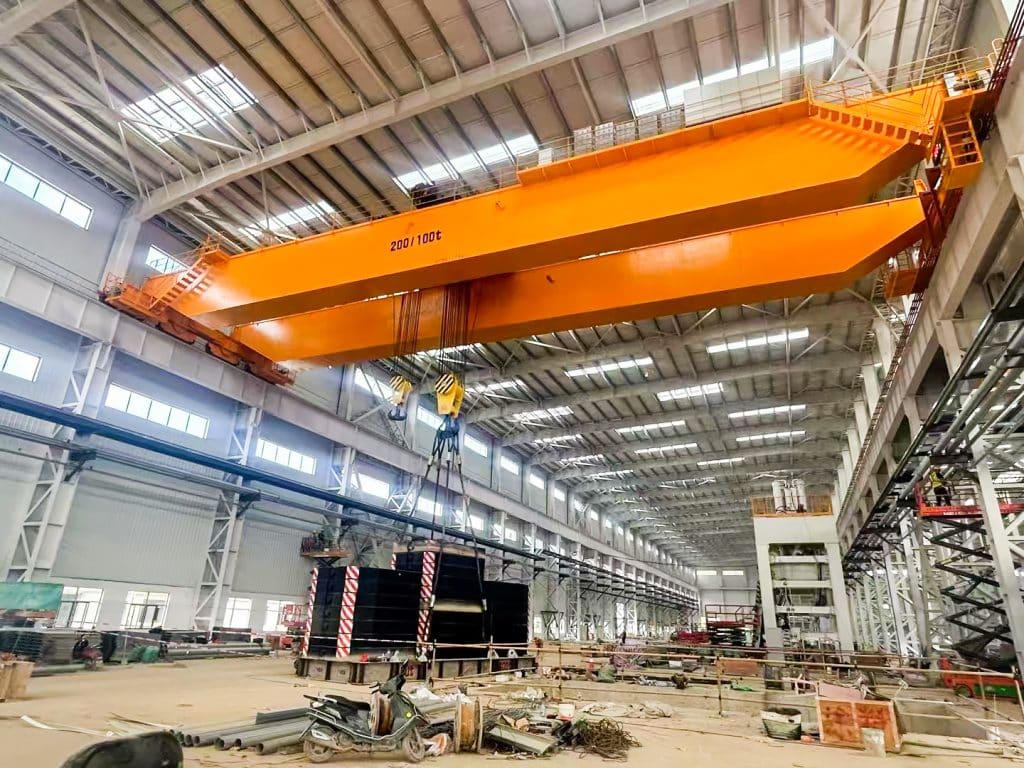

Custom Large-Tonnage Overhead Cranes for Automotive Stamping

In heavy industries, overhead cranes are essential for efficiently moving large, heavy loads. Among these, 200/100 ton overhead cranes stand out for their ability to handle massive weights with precision and safety. At Guanhui, we specialize in designing and manufacturing custom overhead cranes tailored to meet the unique needs of industries like automotive manufacturing, steel production, shipbuilding, and power generation.

Custom Design: Meeting Specific Needs Through Client Collaboration

When it comes to large-tonnage cranes, a one-size-fits-all approach simply doesn’t work. Every industry—and every facility—has its own set of requirements, from the type of loads being lifted to the spatial constraints of the workspace. That’s why custom design is essential for ensuring that a crane not only meets but exceeds expectations.

At Guanhui, we begin every project with in-depth communication with our clients. By understanding their specific needs—such as load capacity, span, lifting height, and control preferences—we can design a crane that fits seamlessly into their operations. For example:

- Span and Lifting Height: Depending on the layout of the facility, the crane’s span (the distance between the rails) and lifting height may need to be adjusted. In automotive mold stamping workshops, where space can be limited, a custom span ensures that the crane can operate efficiently without interfering with other equipment.

- Control Systems: Clients may prefer wireless remote control for greater flexibility or a traditional cabin control system for precision. Our team works closely with clients to determine the best option for their workflow.

- Safety Features: Safety is paramount, especially when dealing with heavy loads. Custom safety systems, such as load monitoring, emergency stop buttons, and anti-collision technology, are integrated based on the client’s operational risks.

By focusing on these details, we ensure that each crane is not just a piece of equipment but a tailored solution designed to enhance productivity and safety.

Understanding the 200/100 ton Overhead Crane: Definition and Functionality

A 200/100t overhead crane is a double-girder bridge crane equipped with two hoists:

- Main Hoist (200 tons): Capable of lifting up to 200 tons, this hoist is designed for the heaviest loads, providing the power needed for major lifting tasks. It is ideal for moving large molds and equipment, ensuring that even the heaviest components can be handled with ease.

- Auxiliary Hoist (100 tons): With a 100-ton capacity, this hoist handles lighter loads or assists in tasks that require more frequent, smaller lifts. It adds versatility to the crane’s operation, allowing it to perform a wider range of functions without compromising on safety or efficiency.

This dual-hoist system is particularly valuable in workshops where both heavy and medium-weight lifting tasks are common. By having both hoists available, operators can switch between tasks quickly, reducing downtime and increasing productivity.

Application in Automotive Mold Stamping Workshops

One of the most demanding environments for overhead cranes is the automotive mold stamping workshop. Here, precision and reliability are critical, as the cranes are responsible for moving large, heavy molds used in the production of vehicle parts. A 200/100t overhead crane is particularly well-suited for this task due to its dual lifting capabilities:

- Main Hoist (200 tons): Used for lifting the heaviest molds and equipment, ensuring that even the largest components can be moved with ease.

- Auxiliary Hoist (100 tons): Ideal for handling lighter or more frequent tasks, such as positioning smaller molds or assisting with maintenance work. This flexibility allows for greater operational efficiency, as the crane can switch between tasks without downtime.

The automotive mold stamping process often involves repetitive, high-precision tasks, and any delay or error can lead to costly downtime. A custom-designed crane, tailored to the specific needs of the workshop, ensures that operations run smoothly and efficiently.

Applications Across Industries

In addition to automotive manufacturing, 200/100 ton overhead cranes are widely used in other heavy industries where moving large equipment and components is a core part of operations. Here are some examples:

- Steel Mills: These cranes are used to transport large steel slabs, coils, and other materials. The main hoist handles the heaviest loads, while the auxiliary hoist assists with smaller tasks, such as positioning or maintenance.

- Shipyards: In shipbuilding, cranes are essential for moving massive ship components, such as hull sections or engines, during assembly. Custom designs ensure that the crane can operate safely within the spatial constraints of the shipyard.

- Power Plants: Overhead cranes are used for handling heavy machinery, such as turbines and generators, during installation and maintenance. The dual-hoist system allows for flexibility in managing both heavy and lighter tasks.

Each of these industries benefits from the custom design approach, as it allows the crane to be optimized for the specific challenges of the environment.

Guanhui’s Success Story: A Custom Crane for an Automotive Workshop

At Guanhui, we take pride in our ability to deliver custom solutions that meet the exact needs of our clients. One of our recent success stories involves designing and installing a 200/100 ton overhead crane for a leading automotive mold stamping workshop.

Project Highlights:

- Custom Span and Height: The workshop had limited ceiling height, so we designed a low-profile crane that maximized lifting height without requiring structural modifications.

- Advanced Control System: The client opted for a wireless remote control system, allowing operators to manage the crane from a safe distance while maintaining full visibility of the workspace.

- Enhanced Safety Features: Given the high-risk nature of the automotive stamping process, we integrated load monitoring sensors and an automatic emergency stop system to prevent accidents.

The result? A crane that not only met the client’s operational needs but also improved workflow efficiency by 30%. This project is a testament to Guanhui’s commitment to delivering high-quality, custom-designed cranes that make a real difference in our clients’ operations.

Why Choose Guanhui for Your Overhead Crane Needs?

When it comes to large-tonnage overhead cranes, experience and expertise matter. At Guanhui, we combine decades of industry knowledge with a client-first approach to deliver cranes that are:

- Tailored to Your Needs: Every crane is designed based on your specific requirements, ensuring it fits perfectly into your workflow.

- Built for Durability: We use high-strength materials and components, such as ABB motors, to ensure long-lasting performance.

- Focused on Safety: Our cranes are equipped with state-of-the-art safety systems to protect both your operators and your equipment.

Whether you’re in automotive manufacturing, steel production, or any other heavy industry, Guanhui is your trusted partner for custom overhead crane solutions.